Storz fire fighting couplings have the same head structure, not distinguish male and female threads. Shapes in suction hose coupling, female thread, male thread and blind cap with chain. When assembly, heads with the same lug distance can be buckled together, which is convenient and fast. Seal ensures the tightness of connecting place. They are used to connect firefighting hose, PVC pipe and other low pressure pipes in the fire brigade, industry, refinery, building industry, agriculture, shipping, military and civil protection.

SFFC-1: Storz suction hose coupling in positive and negative.

SFFC-2: Storz female thread in positive and negative.

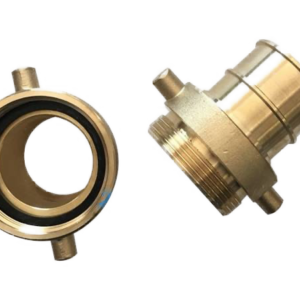

SFFC-3: Storz male thread in positive and negative.

SFFC-4: Storz blind cap with chain in positive and negative.

SFFC-5: Aluminum storz female thread and brass storz male thread can be join together.

SFFC-6: Aluminum storz female thread and brass storz male thread are joining.

SFFC-7: Storz male thread and female thread screw together.

SFFC-8: Join place of storz male thread and storz female thread has seal.

SFFC-9: Brass storz male thread and hose coupling join together through projecting lugs.

SFFC-10: Storz couplings join together through projecting lugs.

SFFC-11: Four storz couplings join together through projecting lugs or thread.

SFFC-12: Storz suction hose coupling and blind cap with chain join together through projecting lugs.

Features of storz fire fighting coupling

- Resistant to corrosion, rust, acid and alkali.

- Easy to install.

- Long service life.

Application of storz fire fighting coupling

Used for connecting fire hose, PVC pipe and other low pressure pipes in the fire brigade, industry, refinery, building industry, agriculture, shipping, military and civil protection.

Production process

We have four methods for products designing and mould making, which is investment casting, forging, die casting and gravity casting. Investment casting includes wax pattern, ceramic shell, investment casting, cut off & grinding and shot blasting. Forging is the method that makes bar go through the process of forging, punching, T6 heat treatment and sandblasting. Die casting is the method that makes aluminum ingot go through die casting, burr removing and grinding. Gravity casting is the method that makes aluminum ingot go through gravity casting, remain removing, T6 heat treatment and sandblasting. After experiencing one of methods, material is processed into semi-finished part, then go through machining and surface treatment, the product is finished. Finally, test products and package products.

Contact us: